You Can’t Fix What You Can’t See: The CFO’s Case for Enterprise-Level Loss Visibility

In a world of razor-thin margins, escalating cost pressures, and volatile supply chains, one truth remains constant for supply chain finance leaders:

You can’t improve what you can’t see.

And yet, many Finance Leaders are flying blind regarding operational losses. Despite decades of investment in Lean, Six Sigma, MES, and ERP systems, the enterprise still lacks one critical thing: a standardized, scalable, financially actionable view of loss across its factory network.

The Illusion of Control

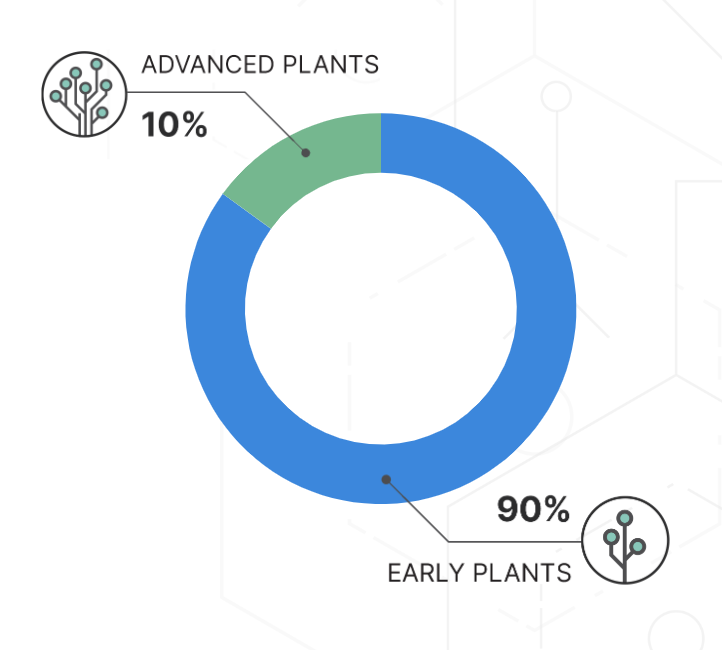

If you manage a global or regional factory network, chances are every plant in your network runs some form of loss analysis.

But ask yourself this:

- Are the metrics consistent across plants?

- Do your dashboards tie directly to financial outcomes?

- Can you confidently say which factory offers the highest ROI for capital investment?

- Do you have visibility of all the opportunities across all factories in a structured way?

- Can you make multi-factories roadmaps and financial decisions rapidly?

If the answer is no, you’re not alone.

A leading Food global supply chain finance leader recently told us:

“If you want to have an enterprise view, it takes effort to get there today.”

The reality is this: local loss visibility is not enterprise insight. And that disconnect is costing you millions.

The Consequences of Fragmentation

Here’s what we see in most multinationals:

Factory-Level | Enterprise-Level |

Data tracked in spreadsheets | No unified platform or taxonomy |

Varying definitions of “loss” | Impossible to compare apples-to-apples |

Ad hoc improvement projects | No strategic prioritization of investment |

Limited financial framing | Weak alignment between ops and finance |

The result?

Decisions are based on who shouts loudest, not where the value actually is.

Finance ends up in a reactive role, supporting cost initiatives without enterprise strategic clarity or confidence.

Why the Finance Leaders Should Care

This isn’t just an operational issue — it’s a P&L problem.

When finance doesn’t have a full view of factory losses:

- Capital is misallocated

- Savings are left on the table

- Transformation roadmaps stall

- And worst of all, there’s no credible way to track ROI

As transformation accelerates — whether through automation, energy optimization, or workforce reskilling — finance must lead with visibility.

Enter SmarterChains: The Operating System for Loss Visibility at Scale

SmarterChains is a SaaS platform built notto replace your MES or ERP — but to bridge the gaps they leave behind.

Here’s what it delivers:

- ✅ One standardized loss framework across every factory

Standardized data collection, benchmarked losses, and unified definitions across all plants. - ✅ Automated enterprise-level rollups

Instantly move from plant-level insights to global visibility — without weeks of Excel wrangling. - ✅Financial-grade analysis

Turn operational data into CFO-ready business cases — complete with NPV, IRR, and payback periods. - ✅ Scenario planning and investment prioritization

Simulate strategies, test trade-offs, and decide where to invest for maximum ROI.

Real-World Impact: What Supply Chain Finance Leaders Gain

- See where your losses really are — and what they’re costing you

- Make faster, smarter capital decisions — grounded in real data

- Hold factories accountable — with shared definitions and clear baselines

- Track progress against financial outcomes — not just operational activities

Final Thought: Visibility Isn’t a Nice-to-Have — It’s a Competitive Advantage

Supply chain finance is evolving. It’s no longer just about closing books and approving budgets — it’s about enabling transformation.

And transformation starts with clarity.

If you want to accelerate cost reduction, enable smart investments, and lead with confidence, enterprise loss visibility isn’t optional — it’s essential.

You can’t fix what you can’t see.

But once you see it?

You can change everything.

| Discover Untapped Potential in Your Manufacturing ProcessPrepare, define, and execute the Industry 4.0 strategies at scale.

|

You might also enjoy: