Take OpEx to the Next Level: How SmarterChains’ Platform Bridges Process Improvement with Tangible ROI

Introduction

Manufacturers worldwide rely on Operational Excellence (OpEx) frameworks like Integrated Work Systems (IWS), Lean, Six Sigma, and TPM to eliminate inefficiencies and drive continuous improvement. These methodologies have transformed production systems by enabling process standardization, empowering employees, and ensuring incremental improvements over time.

However, even the best OpEx programs face fundamental challenges:

- Scalability across multiple factories – What works in one facility often fails to translate across an enterprise.

- Cross-functional alignment – Operational teams optimize for efficiency, but without financial validation, these improvements may not translate into business impact.

- Tracking and sustaining improvements over time – Many companies struggle to consistently monitor their progress, preventing true continuous improvement.

This is where SmarterChains’ value intelligence platform comes in—not as a replacement but as a complementary, data-driven solution that enhances OpEx methodologies by introducing enterprise-wide loss tracking, financial validation, and digital scalability.

The Strengths and Limitations of Traditional OpEx Frameworks

What OpEx Programs Do Well

Operational Excellence frameworks like IWS, Lean, and Six Sigma have revolutionized manufacturing by creating structured, repeatable methodologies for reducing waste and improving performance. Their major benefits include: ✔ Standardized processes – Ensuring consistency in quality and efficiency.

- Employee empowerment – Training operators and leaders to proactively eliminate inefficiencies.

- Incremental improvements – Driving sustained enhancements in operational performance.

Where Traditional OpEx Falls Short

Despite their effectiveness, OpEx frameworks often struggle with:

- Siloed implementation – Loss elimination strategies work within individual plants but are difficult to scale across multiple sites.

- Lack of real-time loss tracking and validation – Most OpEx programs rely on manual assessments and paper-based reports, making it difficult to maintain visibility across an enterprise.

- Financial validation gaps – OpEx methodologies focus on operational efficiencies but often fail to quantify the financial impact of improvements in a way that financial leaders can act upon.

How SmarterChains Enhances Your Existing OpEx Program

SmarterChains integrates seamlessly into existing OpEx programs by digitizing loss identification, tracking, and financial validation across multiple factories.

1. Connecting OpEx to Financial Impact

A key challenge in many OpEx initiatives is demonstrating quantifiable financial value. While IWS, Lean, and Six Sigma focus on optimizing processes, they often lack the tools to measure ROI in financial terms.

SmarterChains bridges this gap by:

- Providing real-time loss quantification with financial modeling.

- Linking operational improvements to P&L impact.

- Enabling CFOs and financial leaders to validate OpEx investments.

2. Enabling Enterprise-Wide Loss Tracking & Benchmarking

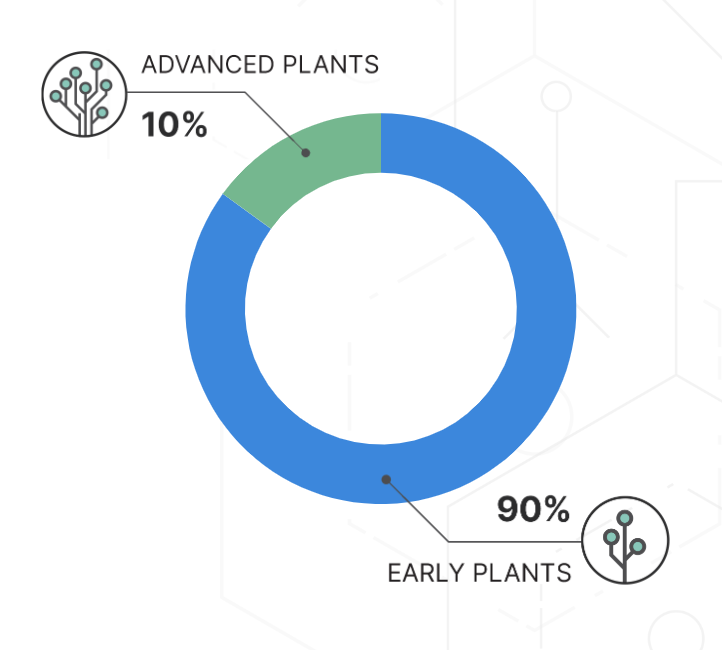

One of the biggest obstacles in scaling OpEx frameworks is the lack of standardization and benchmarking across factories. What works in one plant may not be easily replicated elsewhere due to differences in execution, local practices, or tracking methods.

SmarterChains solves this by:

- Standardizing loss categories across factories to ensure comparability.

- Enabling a digital twin of operations for loss tracking and benchmarking.

- Providing visual dashboards that allow leadership to compare multiple sites and prioritize interventions.

3. Facilitating a Change Management Process for Loss Identification and Recovery

Traditional loss elimination programs rely on periodic audits and manual assessments, making them reactive rather than part of an ongoing, structured process. SmarterChains does not proactively identify losses—instead, it provides a structured framework that enables teams to systematically track, recover, and sustain loss elimination efforts over time.

According to the IMD article on continuous improvement, the key to unlocking value is not simply automating loss detection but creating a structured, sustainable approach to loss elimination that includes: ✔ A transparent, repeatable loss recovery process that aligns OpEx teams with finance and operations.

✔ Digital tracking and reporting tools that eliminate inefficiencies in manual data collection.

✔ Enterprise-wide visualization that enables organizations to sustain improvements over time.

4. Speeding Up Implementation Without Disrupting Existing Workflows

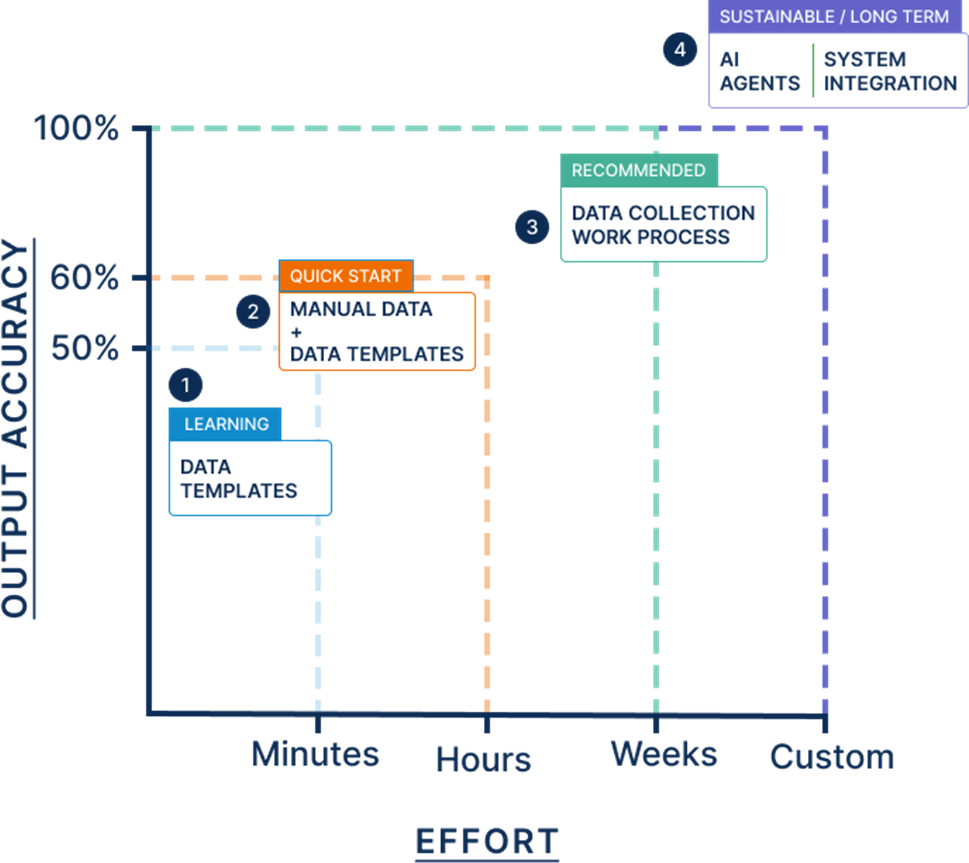

One of the reasons manufacturers hesitate to introduce new digital tools into their OpEx programs is the concern over implementation time and complexity. Unlike traditional loss elimination initiatives, which can take months or years to roll out, SmarterChains delivers actionable insights in hours, not months.

To learn more about our Value Intelligence Platform, our Value Finder, Value Builder and how we can make it easy for you and your colleagues to obtain tremendous value in just hours, book a DEMO

Conclusion

If your company already has a strong IWS, Lean, or Six Sigma program, you are ahead of the curve. However, without enterprise-wide benchmarking, real-time loss tracking, and financial validation, even the best OpEx programs can fall short of their full potential.

SmarterChains provides the missing link by:

- Connecting OpEx initiatives to measurable financial impact.

- Standardizing loss tracking and benchmarking across multiple factories.

- Enabling structured, sustainable loss identification and recovery processes.

By integrating SmarterChains into your existing OpEx framework, you don’t replace what’s working—you make it even more powerful.

Book A Demo to discover how the Value Intelligence Platform can accelerate your journey to ongoing Value Creation.

Read more about our commitment to continuous improvement in this foundational article co-authored with the IMD Business School.

| Discover Untapped Potential in Your Manufacturing ProcessPrepare, define, and execute the Industry 4.0 strategies at scale.

|

You might also enjoy: